Oil and gas companies are required to precisely track the quantity of product in their pipelines on a monthly basis, ensuring that all system inputs and outputs are accurately reconciled. This has traditionally been a challenging and labor-intensive task, occupying the measurement team for the first part of each month.

Oil and gas companies are required to precisely track the quantity of product in their pipelines on a monthly basis, ensuring that all system inputs and outputs are accurately reconciled. This has traditionally been a challenging and labor-intensive task, occupying the measurement team for the first part of each month.

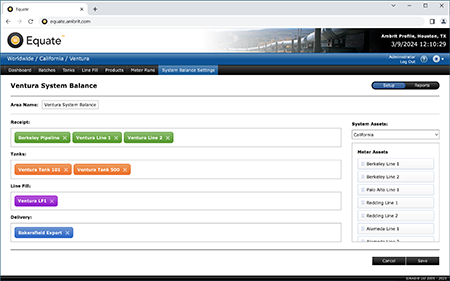

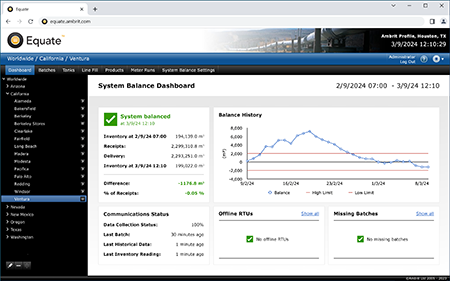

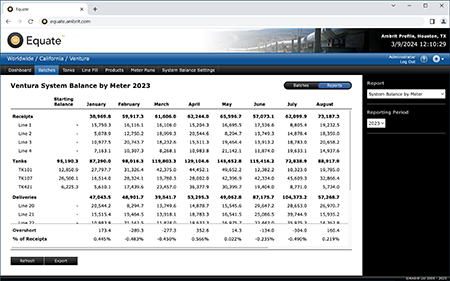

Equate™ streamlines the system balancing process, making all the required information readily available to simplify the end-of-month reporting.

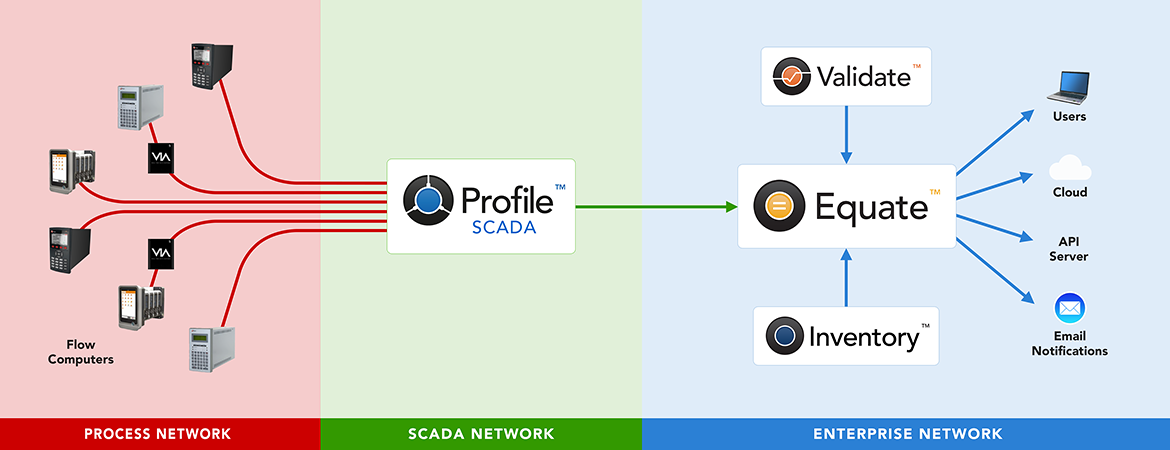

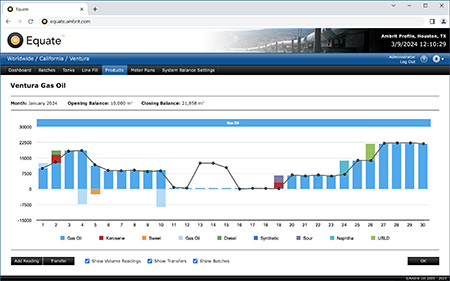

System balancing is integrated directly with the flow computer data, providing a much better insight into the state of the measurement and allowing system balances to be based on higher resolution custody transfer data rather than just a single total taken from the batch report.

Real-time secondly data from receipt and delivery meters can be combined with tank volumes and line fill to give an accurate picture of the system balance that tracks all product movements across the system.

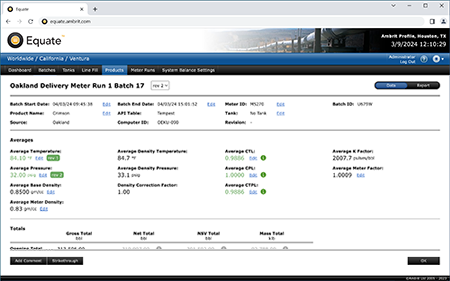

Modifications to batches are executed on an individual basis and batch totals are recalculated automatically. A mismeasurement report documents the impact of every change on the measurement totals. This report includes complete revision control to ensure full traceability back to the flow computer.

At the end of each month, Equate™ generates a suite of high-quality PDF reports summarising the state of the system balance, which can automatically be distributed to interested parties.

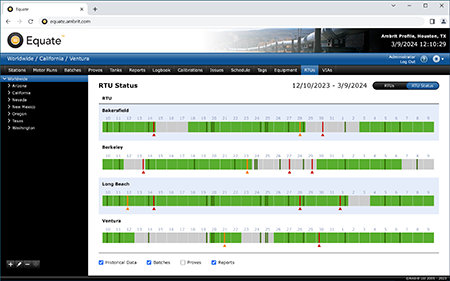

Combining Equate™ with other applications in the Metrology suite provides a complete picture of the quality of the overall state of measurement for all measurement stations, tracking the state of the proves, calibrations and uncertainty for all equipment on the station.